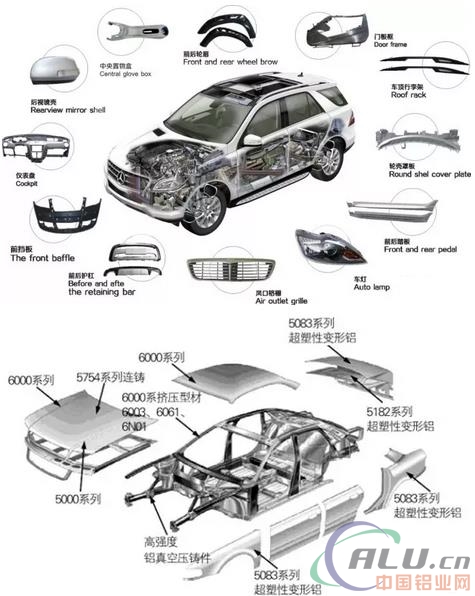

[China Aluminum] The rapid development of the automotive industry, but the growing urgency of energy issues, the environmental issues caused by the car also received much attention. The development of new energy automobile industry is a way to ease the energy crisis, reduce greenhouse gas emissions, and reduce environmental pollution. At present, new energy vehicles have become an important direction for the reform of the automobile industry. With the large number of new energy vehicles used in domestic cars, official vehicles, buses, taxis, and logistics vehicles, according to statistics, the annual sales of new energy vehicles in China will reach the total market demand in 2020. More than 5% will initially be built into a new energy automotive industry system that is market-oriented, where enterprises are the mainstay, and where production, education and research are closely integrated. From 2025 to 20%, an independent and controllable integrated industrial chain will be formed. Under the national target of total carbon emissions and the demand for primary energy alternatives, the annual sales of new energy vehicles in 2030 will continue to increase substantially, and the scale will exceed 10 million yuan. Vehicle. With the implementation of the new energy vehicle strategy, China will not start late. As early as 2001, the development of new energy vehicles was included in the “863†major scientific and technological topics during the “10th Five-Year Plan†period. In recent years, governments at all levels have adopted policies such as subsidies for buying cars and giving priority to licensing in order to promote the consumption of new energy vehicles. The demand and development of new energy vehicles will drive the development of various types of automotive batteries, light weight vehicles, and auto parts and components industries under the new energy era, and will also bring infinite opportunities for the Chinese aluminum industry. Different from traditional automobiles, new energy vehicles use batteries as the driving force to drive the automobiles. They are subject to the weight of power batteries, the constraints of the battery range of the power batteries, and the high pressure of automobile energy-saving and emission reduction policies. The vehicle body is used in vehicle design and material applications. Lightweight has become the first issue for car companies to consider. Therefore, battery-powered new energy vehicles are more in need of weight reduction than traditional cars. This also opens up a broader market for lightweight materials such as aluminum. In lightweight automotive materials, the overall cost-effectiveness of aluminum alloy materials is higher than that of steel, magnesium, plastics, and composite materials, and it has comparative advantages in terms of application technology, operational safety, and recycling and utilization. The density of aluminum material is only 1/3 of that of steel, and its weight reduction and energy saving effect are obvious, and it can better enhance the riding comfort under the premise of ensuring safety. At the same time, aluminum materials are easier to recycle and recycle. The comprehensive cost-performance advantage of aluminum determines its choice as a lightweight vehicle application. The application of aluminum in new energy auto parts includes bodywork, wheels, chassis, anti-collision beams, floors, power batteries, and seats. According to the classification of processing methods, aluminum used in automobiles is mainly divided into three forms: die-casting, extrusion and rolling. Among them, the amount of die castings accounts for about 80%, and the extrusions and rolling pieces each account for about 10%. Die-casting parts are mainly used for engines, wheels, etc. Extrusion parts are mainly used in seat frames, luggage racks, door beams, etc., while the press parts are mainly used to produce aluminum plates for bodywork. Among them, the body consists of a body frame made of high-performance aluminum profiles and skins and doors made of high-precision aluminum plates; aluminum alloy wheels (cast aluminum or forged aluminum wheels); and the chassis includes high-strength large-section aluminum structural members and aluminum Alloy forgings; bumper beam bumpers made of profiles; new energy passenger car floor; lithium ion battery including battery positive aluminum foil, battery aluminum case and battery aluminum tray (Europe and the United States battery trays are all aluminum alloy material, domestic battery trays have aluminum alloy Material, stainless steel, etc.; New Energy Bus Seat System. In the past, new energy vehicles mostly used steel materials to make electric vehicle power battery trays. Nowadays, many companies use aluminum alloy materials as the mainstay. The density of aluminum alloy is 2.7g/cm3, and aluminum alloy has obvious advantages in terms of compression and welding. The density of magnesium alloy is 1.8g/cm3, and carbon fiber is 1.5g/cm3. These materials are used to produce battery trays, which will greatly improve the lightweighting of new energy vehicles. It is understood that the battery aluminum tray mainly uses 6 series aluminum profiles. Good plasticity and excellent corrosion resistance, especially stress corrosion cracking tendency, good welding performance, making 6 series aluminum profiles are very suitable for the application of this project. In order to ensure product quality, it is necessary to adopt advanced welding techniques such as friction stir welding to ensure that the product is integrally formed. The amount of aluminum used in new energy automobiles is more than that of ordinary automobiles. The rapid development of China's new energy vehicles will certainly promote the development potential of aluminum in the new energy vehicle market segment. Aluminum processing companies will seize this opportunity for development and R&D. High-performance, highly adaptable aluminum materials or deep-processed aluminum parts undoubtedly open up new sales orientations for the diversified application needs of new energy vehicles. Light Power Box,Aluminum Extrusion Box,Aluminum Light Enclosure,Extrusion Enclosure Support Dongguan Formal Precision Metal Parts Co,. Ltd , https://www.formalmetal.com